All Products

-

Battery Cell Making Machine

-

Battery Welding Machine

-

Battery Coating Machine

-

Battery Mixing Machine

-

Lithium Battery Raw Material

-

Lithium Ion Battery Testing Equipment

-

Laboratory Ball Mill Machine

-

Battery Rolling Machine

-

Glove Box For Lithium Battery

-

Battery Pack Production Machine

-

Lithium Battery Production Line

-

Laboratory Muffle Furnace

-

Laboratory Tube Furnace

-

Customer oneGood quality, fast ship, highly recommend

Customer oneGood quality, fast ship, highly recommend -

Customer TWOThe texture is very good. No problem with current use, very good. The operation is very simple and cost-effective

Customer TWOThe texture is very good. No problem with current use, very good. The operation is very simple and cost-effective

Contact Person :

Eilene

Phone Number :

+86 15382821093

WhatsApp :

+8615382821093

AC100V Battery Cell Making Machine , Vacuum Battery Heat Sealer for Pouch Cell

Product Details

| Model | ZK-HS200 | Working Voltage | AC100V/220V 50/60Hz |

|---|---|---|---|

| Head Temperature | Max. 250 ℃ | Dimensions | L600mm * W640mm * H1460MM |

| Weight | 500KG | Battery Size | Max. L180 * W135 * H15mm |

| High Light | battery disc vacuum final sealing machine,Pouch battery vent sealing machine,Pouch battery automatic sealing machine |

||

Product Description

Lithium Battery Automatic Vacuum Heat Sealer Sealing Packaging Machine for Pouch Cell Second Final Sealing after electro

-

-

Rotary disc vacuum final sealing machine

ZK-HS200 rotary disc vacuum final sealing machine can be applied to the puncturing and secondary vacuum final sealing process of flexible packaging lithium batteries. The machine adopts a turntable design, which can realize many functions such as manual loading and unloading, automatic vacuum exhaust, piercing and drainage, heating sealing. The vacuum of the working chamber of the equipment is maintained well, the sealing effect is high, and the flatness of the finished battery is good.

It is applied to the puncture and final sealing of soft pack batteries, and is compatible with batteries of a certain size range; Double-station turntable structure, single group piercing and head design; The vacuum is kept good to ensure the moisture content of the finished battery; Using soft sealing method, good temperature uniformity, high packaging consistency and long service life; Acupuncture piercing function to discharge excess electrolyte from the battery; PLC control, HMI operation, adjustable sealing pressure and time;

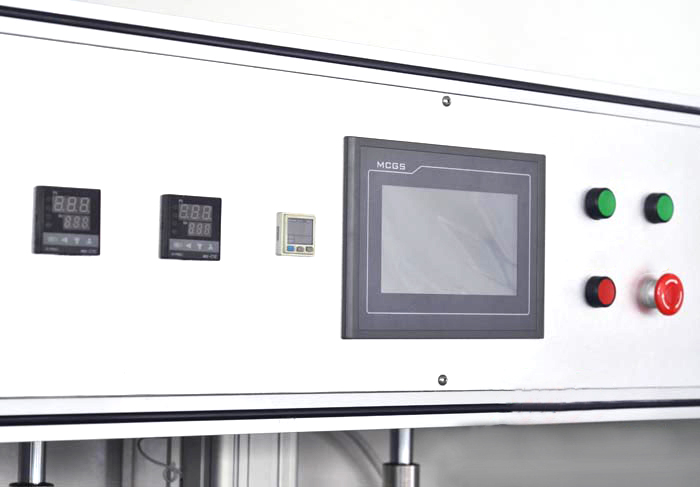

PLC touch screen control

This equipment adopts PLC touch screen control to monitor the operation parameters of the equipment throughout the process, which is convenient for users to adjust.

Independent cylinder control

The sealing, pressure plate and bayonet are controlled by separate independent cylinders, which can control the movement of individual components at will.

Battery placement

The open battery placement position is convenient for placing and handling the battery. The placement position is flat and the position can be adjusted.

Recommended Products