-

Battery Cell Making Machine

-

Battery Welding Machine

-

Battery Coating Machine

-

Battery Mixing Machine

-

Lithium Battery Raw Material

-

Lithium Ion Battery Testing Equipment

-

Laboratory Ball Mill Machine

-

Battery Rolling Machine

-

Glove Box For Lithium Battery

-

Battery Pack Production Machine

-

Lithium Battery Production Line

-

Laboratory Muffle Furnace

-

Laboratory Tube Furnace

-

Customer oneGood quality, fast ship, highly recommend

Customer oneGood quality, fast ship, highly recommend -

Customer TWOThe texture is very good. No problem with current use, very good. The operation is very simple and cost-effective

Customer TWOThe texture is very good. No problem with current use, very good. The operation is very simple and cost-effective

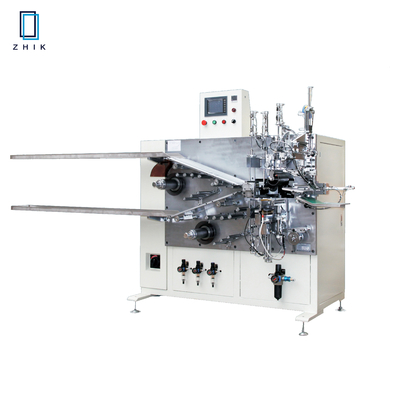

Semi Automatic Battery Winding Machine for Cylindrical Cell 18650 26650 32650

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Model | ZK-ws-18650 | Diaphragm Width | 20 ~ 65 Mm |

|---|---|---|---|

| Width Of Pole Piece | 18 ~ 63 Mm | Length Of Pole Piece | 200 ~ 1500 Mm |

| Scope Of Application | 6 ~ 10 PPM | Equipment Capacity | Max. L180 * W135 * H15mm |

| Highlight | Battery Winding Machine,Winding Equipment For Cylinder Cell,Lithium Ion Battery Making Machine |

||

Pouch Cell Cylindrical Cell 18650 26650 32650 Semi-Automatic Lithium Battery Electrode Winder Winding Equipment Machine

-

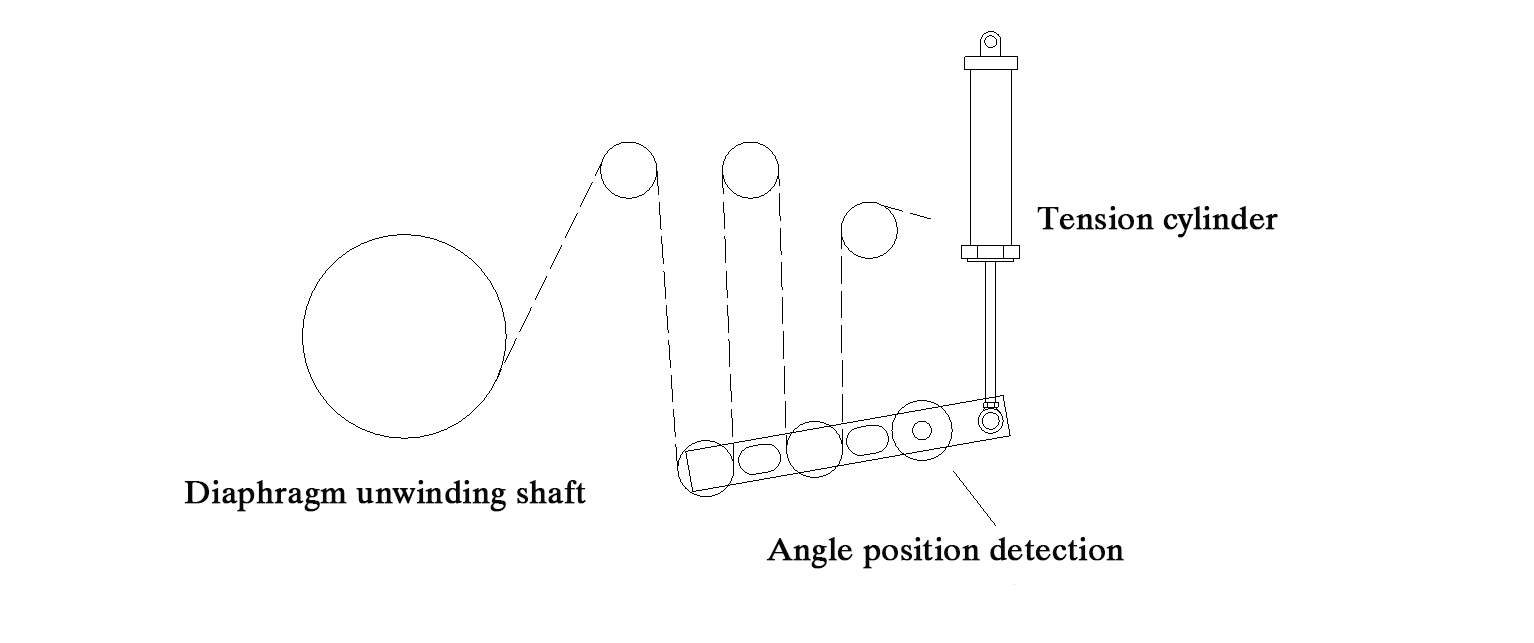

Battery winding machine

The latest original variable angle speed rotation technology makes the linear speed of the diaphragm and pole piece feed relatively constant, that is, to achieve the purpose of constant tension during the winding process, and to ensure that the battery core is wound neatly and uniformly. The two-roll diaphragm is unwinding actively, and the diaphragm tension signal is detected in real time by an encoder connected to the tension swing arm shaft. After being processed by the PLC, the diaphragm unwinding stepper motor actively follows the tension change and variable speed unwinding to achieve constant diaphragm tension purpose. At the same time supplemented by the company's latest cylinder tension control technology, the tension can be automatically and smoothly adjusted during the winding process