-

Battery Cell Making Machine

-

Battery Welding Machine

-

Battery Coating Machine

-

Battery Mixing Machine

-

Lithium Battery Raw Material

-

Lithium Ion Battery Testing Equipment

-

Laboratory Ball Mill Machine

-

Battery Rolling Machine

-

Glove Box For Lithium Battery

-

Battery Pack Production Machine

-

Lithium Battery Production Line

-

Laboratory Muffle Furnace

-

Laboratory Tube Furnace

-

Customer oneGood quality, fast ship, highly recommend

Customer oneGood quality, fast ship, highly recommend -

Customer TWOThe texture is very good. No problem with current use, very good. The operation is very simple and cost-effective

Customer TWOThe texture is very good. No problem with current use, very good. The operation is very simple and cost-effective

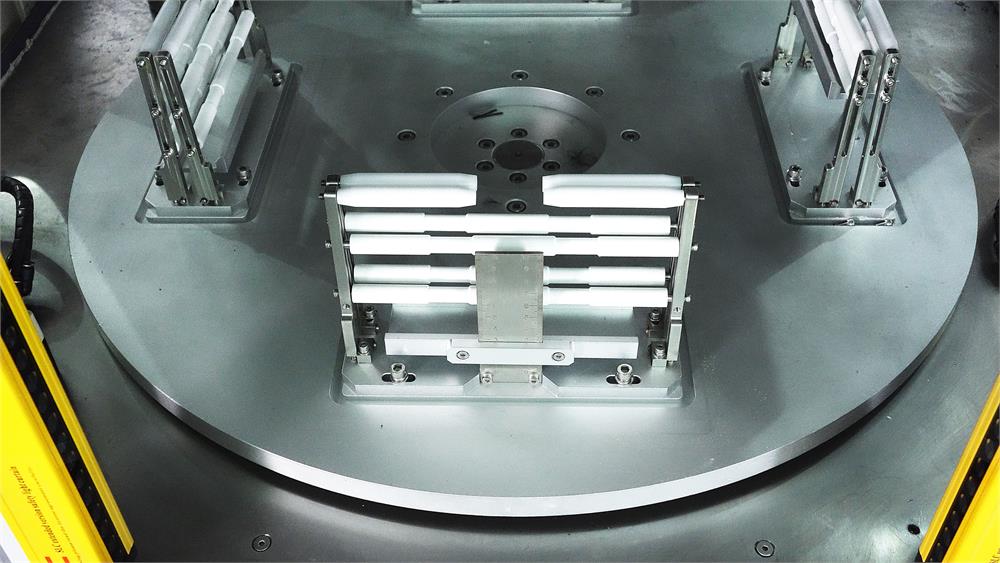

Vacuum Sealing Battery Cell Making Machine 3 In 1 5KW power 110V 220V

| Model | ZK-ZY4 | Power | 5KW |

|---|---|---|---|

| Voltage | 110V/220V | Battery Length | 24-45mm |

| Airbag Width | ≥32mm | Total Battery Length | ≤60mm |

| High Light | 3 in 1 liquid injection machine,Pouch battery liquid filling and sealing machine,Automatic liquid injection and sealing machine |

||

Pouch Battery Pilot line semiauto 3 In 1 Vacuum Sealer sealing machine w Integrated Electrolyte Injection & Diffusion St

3 in 1 liquid injection machine

ZK-ZY4 is a semi-auto three-in-one vacuum sealer with a four-position rotational platform for the stream-flow processes of

pouch battery fabrication including electrolyte injection, electrolyte diffusion & degassing and vacuum hot sealing. It features

an air-tight chamber with a front observation window and operation gloves which allow the operation under moisture and oxygen free

environment. In this technique, the pouch cell is loaded in station#1 following the electrolyte injection in station#2. Then, the

cell will be transferred to station#3 for vacuum degassing & diffusion which helps with electrolyte wetting over the electrode

materials. Finally, the cell will be transferred to station#4 for gas removal and hot seal under vacuum condition. This is an

ideal system for pilot scale pouch battery manufacturing with accurate and efficient workflow.